MD+DI: CNC Creation Highlights Complex Machining Capabilities of Autocam Medical

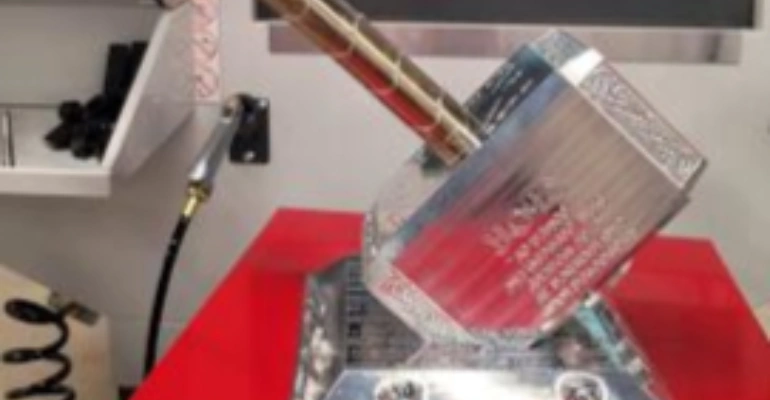

Two graduates of Autocam Medical’s CNC machinist apprentice program were honored about a year ago for their version of Thor’s hammer, which they created as part of the program.

Wrindy Hauser and Ethan Richey, machined a Thor’s hammer in the AMP Lab, which is where classes for the apprentice program are held. The students later won a first-place prize in Mastercam’s global Master of CAM Wildest Parts Machining Competition in the teams division.

Wrindy Hauser and Ethan Richey, machined a Thor’s hammer in the AMP Lab, which is where classes for the apprentice program are held. The students later won a first-place prize in Mastercam’s global Master of CAM Wildest Parts Machining Competition in the teams division.

It’s “not necessarily easy to see from afar, but the level of detail and the complexity of the parts that came together to make the hammer has many similarities with devices or customers’ requests of us,” John Kennedy, IV, general manager of Autocam Medical, told MD+DI in an interview last year.

Kennedy said that Autocam Medical continues to see growing demand for complex instrumentation and growing complexity of the instrumentation that the machine shop is asked to provide by OEM medical device customers.

“We see this continuing to drive demand for CNC Machining,” he said.

Indeed, the global CNC machining market is projected to grow to $150 billion by 2029, Jake Hall, the Manufacturing Millennial, noted in a LinkedIn post Monday.

“This massive opportunity is making manufacturers capitalize on leveraging automation [and] robotics to compete globally,” Hall said.

In the post, he also recalls programming his first CNC during college to create a keychain.

“Today one of the biggest challenges in our industry is that many small and medium-sized machine shops don’t have the skilled workers to run or operate machines or even interested workers to be trained and are learning how to leverage automation,” said Hall, who is a manufacturing thought leader known for his passion for automation, and attracting a new generation of skilled workers to the field.