Celebrating our newest apprenticeship program graduates

On February 9th, we gathered in the AMP Lab to celebrate our…

MD+DI: CNC Creation Highlights Complex Machining Capabilities of Autocam Medical

Two graduates of Autocam Medical’s CNC machinist apprentice…

2023 apprenticeship program graduates

Once again we gathered in the AMP Lab to celebrate our newest…

GRCC WORKFORCE WEDNESDAY: Apprenticeship Program Helps Student Acquire an Education and a Career

GRCC Workforce Training programs provide in-demand skills leading…

INDUSTRY WEEK: Autocam Medical’s Apprenticeship Program Gives Students a Job and Pays 100% of Their College Tuition

Autocam Medical looked into the future, back in 2016, and saw…

MIDWEST MANUFACTURING NEWS: Autocam Medical’s Apprenticeship Program Provides Students With the Best of Both Worlds

Autocam Medical, a global contract manufacturer of precision…

MANUFACTURING NEWS: Autocam Medical Apprentice Program Aims To Ease CNC Machinist Shortage

Autocam Medical, a global contract manufacturer of precision…

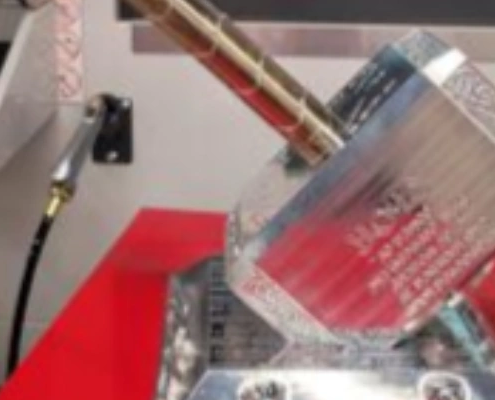

MD+DI: Autocam Medical Apprentices Win Global Mastercam Machining Competition

What does Thor’s hammer have to do with medical device manufacturing?…

MODERN MACHINE SHOP: Autocam Medical’s Earn-While-You-Learn Apprenticeship Program Addresses CNC Machinist Shortage

Autocam Medical, a global contract manufacturer of precision…

MIBIZ: Autocam Medical Remains Optimistic About Building Talent Pipeline

Last month, Autocam Medical Devices LLC graduated its fourth…

WGVU: Autocam Medical Opportunities Pave the Way for Fulfilling Career

Autocam Medical was recently approached by WGVU to discuss their…

GRCC TODAY: Autocam Medical Apprentices Earn While They Learn for Free

Autocam Medical, a global contract manufacturer of precision…